A gold finger PCB is a printed circuit board that features gold-plated contact fingers along the edge of the board. These “gold fingers” are designed to plug into connectors or slots, allowing the PCB to interface securely with other electronic components or systems. The gold plating provides excellent electrical conductivity, corrosion resistance, and wear durability, making it ideal for repeated insertion and removal.

Gold finger PCBs are commonly used in applications where reliable edge connections are critical. From computer expansion cards to industrial control systems, this PCB type ensures stable signal transmission and long-term performance in demanding environments.

Structure and Design of Gold Finger PCBs

The defining feature of a gold finger PCB is the edge connector area, where copper pads are plated with a layer of hard gold over a nickel barrier. This structure prevents oxidation and reduces contact resistance during operation.

Beyond the gold fingers, the rest of the PCB may be single-layer, multilayer, or high-density depending on application requirements. Careful attention is given to pad spacing, beveling angles, and plating thickness to ensure smooth insertion and consistent electrical contact.

Why Gold Plating Is Used in Gold Finger PCBs

Gold is used in gold finger PCBs because of its superior electrical and chemical properties. Unlike other metals, gold does not oxidize, which ensures stable contact resistance over time.

Hard gold plating is especially important for edge connectors that experience mechanical wear due to repeated insertion cycles. The nickel underlayer adds strength and improves adhesion, while the gold surface provides excellent conductivity and durability.

This combination makes gold finger PCBs highly reliable in applications where connection integrity is essential.

Key Advantages of Gold Finger PCB Technology

One of the main advantages of gold finger PCBs is excellent electrical performance. Low contact resistance ensures efficient signal transmission and minimizes power loss.

Gold finger PCBs also offer exceptional durability. The hard gold surface withstands repeated mechanical stress without significant wear, making these boards suitable for long-term use. Additionally, they provide strong resistance to corrosion, moisture, and environmental contaminants.

These advantages contribute to improved system reliability and reduced maintenance requirements.

Common Applications of Gold Finger PCBs

Gold finger PCBs are widely used in computer hardware such as graphics cards, memory modules, and network interface cards. The gold-plated edge connectors allow these components to interface reliably with motherboard slots.

In industrial electronics, gold finger PCBs are used in control modules, programmable logic controllers, and automation systems. Telecommunications equipment, test and measurement devices, and medical electronics also rely on gold finger PCBs for secure and stable connections.

Their versatility makes them suitable for both consumer and industrial-grade applications.

Gold Finger PCB vs Standard Edge Connector PCB

Compared to standard edge connector PCBs that use tin or other surface finishes, gold finger PCBs offer significantly better performance and longevity. Tin finishes are more prone to oxidation and wear, which can lead to increased contact resistance over time.

Gold finger PCBs maintain consistent electrical performance even after thousands of insertion cycles. While they have a higher initial manufacturing cost, their durability and reliability often result in lower total cost of ownership.

Designers typically choose gold finger PCBs for applications where reliability and long-term performance are critical.

Design Considerations for Gold Finger PCBs

Designing a gold finger PCB requires precise attention to connector dimensions, plating thickness, and edge beveling. Beveled edges help guide the PCB into connectors smoothly and reduce wear on both the board and the mating connector.

Spacing and alignment of the gold fingers must be carefully controlled to meet connector specifications. Masking during the plating process is also important to ensure that gold is applied only to the intended contact areas.

Working with an experienced manufacturer during the design phase helps ensure that all mechanical and electrical requirements are met.

Manufacturing Process of Gold Finger PCBs

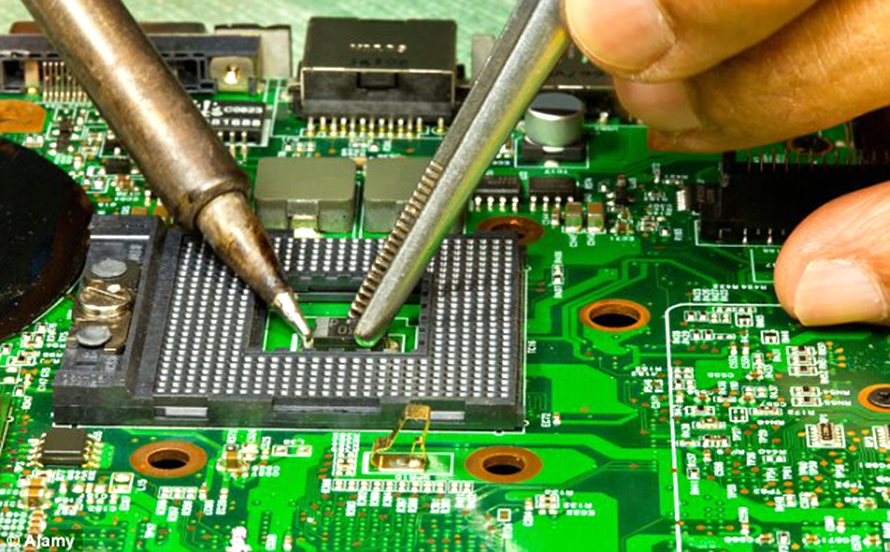

The manufacturing process of gold finger PCBs involves several specialized steps. After standard PCB fabrication, the edge connector areas are selectively plated with nickel and hard gold.

This selective plating process requires precise masking and strict control of plating thickness. Additional steps such as edge beveling and polishing are performed to ensure smooth insertion and reliable contact.

Quality control measures, including visual inspection, thickness measurement, and electrical testing, are essential to ensure consistent performance and durability.

Quality Standards and Testing

Gold finger PCBs are often manufactured to meet strict industry standards, especially for applications in telecommunications, automotive, and industrial electronics. Testing may include contact resistance measurement, durability testing, and environmental stress testing.

These quality assurance processes help verify that the gold fingers can withstand repeated use and harsh operating conditions without degradation.

Choosing a manufacturer with robust testing capabilities is essential for achieving reliable results.

How to Choose the Right Gold Finger PCB Manufacturer

Selecting the right gold finger PCB manufacturer is critical to ensuring quality and reliability. A capable manufacturer should have experience with selective gold plating, edge connector design, and precise machining processes.

Look for manufacturers that offer design support, strict quality control, and compliance with international standards. Advanced inspection equipment and a proven track record in producing gold finger PCBs are strong indicators of reliability.

An experienced manufacturing partner can help optimize your design for performance, durability, and cost efficiency.

Final Thoughts

Gold finger PCBs play a vital role in modern electronics by providing reliable, durable, and high-performance edge connections. Their excellent electrical properties and resistance to wear make them indispensable in applications where connection integrity is essential.

If your project requires dependable edge connectivity and long-term performance, partnering with a trusted gold finger pcb manufacturer is the key to success. The right manufacturer will deliver high-quality, production-ready gold finger PCBs that meet the demanding standards of today’s electronic systems.