Introduction

In more contemporary manufacturing, custom CNC milling orders are no longer insulated from common challenges such as design redo, cost variance, and timeline changes owing to imprecise communication. The problem is essentially caused by information bottlenecks in more traditional supply chain systems, in which design and manufacturing divergence increase complications arising from errors.

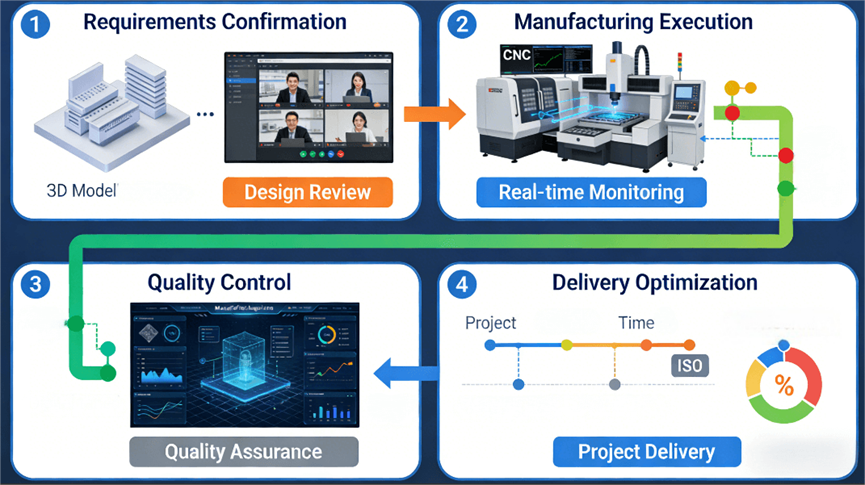

This discussion will show that by improving projects through the simultaneous optimization of precision manufacturing and communication approaches, smooth transitions from proto to main manufacturing are made possible. The discussion will expand on how communication principles in key manufacturing process areas can ensure maximum effectiveness and minimum complications.

Why Do Communication Breakdowns Lead to 80% of Errors in Prototyping in CNC Milling?

Communication plays a crucial role in prototyping in CNC milling. Misinterpretation in the drawing or tolerance limit may result in a major error. Case studies from authoritative sources, such as NASA, prove the impact of lack of communication in complex tasks, which results in more than 80% prototyping error, which may be caused due to minor miscommunication.

1. The Role of Authority Standards in Communication Failures

While referencing standards like ASME Y14.5, where geometric dimensioning is given particular importance, ambiguous tolerance definition in the course of design reviews often causes misplaced expectations. For example, unclear annotations in a CAD system may cause errors in the toolpath definition and result in misplaced parts. Accuracy in communication helps ensure that all parties are on the same page with reference to expectations, aligning with the standard of excellence in a project like the aircraft project.

2. Common Errors in CNC Prototyping Caused by Miscommunication

Typical problems might be incorrect material specification, or important design elements overlooked, often a consequence of insufficient briefings. A fuzzy tolerance annotation, for instance, could lead machinists to adopt conservatively specified parameters. Incorporating extensive design review meetings into a customized CNC milling services will allow for better understanding and reduce prototype development time by up to 40%.

3. Case Study: How Structured Communication Prevents Reprocessing

A case in point is a medical device part for which there had been confusion in communication about surface finish, causing three cycles of prototyping. The project team introduced a checklist for design feedback, removing confusion and reducing costs by 30%, thus proving that proactive communication turns the prototyping process into an efficient phase, just like what NASA practices for its mission-critical reviews.

How Can an End-to-End CNC Milling Partner Act as Your Communication Bridge?

A full-cycle CNC milling service provides a central point that links design, processing, and quality checks, as seen in the principles for building relations in team working. Using one point of contact reduces the risk inherent in information transfer, as seen in point-to-point communication. Standards, for instance, ISO 9001:2015, as illustrated by link 2, verify that harmonized communication processes are important for quality management, as utilized by a full-cycle CNC milling service.

- ISO 9001 Framework for Standardized Communication: ISO 9001 makes it mandatory for organizations to ensure proper communication channels for quality objectives, including audits and feedback. Applying it to CNC milling, there would be live updates and confirmation at checkpoints, avoiding any deviations. For example, organizations following it cut down their response time by 50% for any reply related to emails, ensuring trust and integrity.

- Advantages of Having a Single Partner in Streamlining Workflows: In contrast, for a multi-vendor integration, loss of context between the stages is a typical concern because the communication risk is not taken into account by an integrated partner. For instance, a supplier’s adherence to ISO procedures ensures that design review feedback is accurately translated into production plans, thereby preventing misinterpretations.

- Improving Collaboration via Online Tools: More-advanced platforms such as project management software make it all possible by keeping everything monitored and adjusted constantly. For instance, simulation technology using digital twins helps partners forecast any problems prior to machining. This is consistent with ISO 9001’s continuous improvement theme where communication is a constantly changing tool as opposed to a static process.

What Are the Hidden Costs of Poor Communication in Production Ramp-Up Phases?

Communication issues during the scaling of production cause indirect costs like machine downtime, material losses, and unexpected delays. It has been revealed that manufacturing projects with no record of communication costs 15% more in total costs due to reactive changes. Meanwhile, effective communication plans like daily syncs and risk warnings help reduce such costs.

1. Defining Losses Caused By Communication

It is found from industry analysis data that an average schedule overrun of 20% is caused by miscommunication in ramp-up activities, which is mostly because of machine reprogramming and material scrap. This would be because an incorrectly understood specification requirement can lead to rejecting an entire lot, thereby highlighting the importance of accurate instructions.

2. Implementation of Proactive Communication Checklist

A structured checklist that covers points such as change confirmations and stakeholder sign-offs has the advantage of ensuring consistency among all stakeholders. It decreased unexpected interruptions by 35% on an automobile project that illustrated the significance of structured communication as a cost-effective mechanism.

3. Leveraging Technology for Real-Time Adjustments

Smart factories use IoT-enabled sensors for data on product metrics so that changes can be instantly conveyed through communication. This also mirrors best practices in high-stakes sectors, wherein real-time feedback loops ensure small mistakes do not amplify and thus ultimately help protect budgets.

How Does Precision CNC Milling Mirror Interpersonal Responses?

Precision milling, tolerances down to ±0.01mm, is an example that translates to an effective response in social dynamics because attention to detail is critical. Adaptability is also essential in both examples. For example, in machining parts for medical application, precision in communication is used to prevent accidents through confirmation of each change.

1. Analogies Between Mechanical Precision and Communication Accuracy

Just as a CNC machine can alter its path of tools in relation to real-time information, so too can an interpersonal response. This analogy supports the idea that precise communication in manufacturing, as in an interpersonal reaction, has an integral role in developing trust and in preventing errors.

2. Case Example: Medical Part Machining and Communication Protocols

There was a healthcare component that had to meet very strict requirements for biocompatibility, and with change orders and team briefings, the project prevented divergence that might have generated product recalls. This illustrates the essential interplay of dialogue and detail work for success to happen.

3. Integrating Feedback for Continuous Refinement

Conducting audits and feedback from customers help improve processes in mills in a manner akin to how feedback helps in improving people interactions. Adopting a culture of continuous improvement in manufacturing will help in achieving the desired consistency in the manner of ISO 9001.

What Should You Prioritize When Choosing a CNC Milling Service Provider?

Choosing the right partner includes assessing technical competence, quality systems, and responsiveness to communication. Avoiding pitfalls, such as neglecting certification needs, will ensure smooth partnership cooperation. Putting manufacturing solutions above all else that meet standards will guarantee success in any project.

- Key Evaluation Criteria: Certifications and Technical Expertise: Other certification such as ISO 9001 and AS9100D is an assurance of the commitment to the quality of the partners and the use of clear communication. For example, the certification helps in minimizing risks by 30% in a project.

- The Role of Communication Speed in Decision-Making: The time an associate takes to answer inquiries or changes can either make or break a timeline. Solutions such as specialized platforms reduce delays by half, while highlighting how responsive collaboration is as important as machining tolerances.

- Avoidance of Pitfalls via Due Diligence: Through referencing lessons from industry guides, due diligence should involve the consideration of project and customer testimonies in order to avoid potential misalignment and ensure the communication framework of the partner supports and promotes efficiency in the longer term.

Conclusion

Precision in communication coupled with advanced CNC milling provides a dual engine toward the success of a project. The benefits of structured collaboration include up to 30% reduction in risks. Standardized protocols and the choice of partners having robust systems allow manufacturers to turn complex projects into streamlined work. To tap this advantage, the experts ensuring clarity and quality can be consulted.

FAQs

Getting a project management site where things can be updated in real time, so it reduces response time by doing those things through emails, by at least 50%.

Yes, because early alignment helps avoid costly changes down the line. For example, specifying tolerance calls in the initial discussion can reduce prototype iteration times by as much as 40%.

The company holds certifications in ISO 9001, AS9100D, and IATF 16949. All these certifications include rigorous documentation and communication processes, and are audited every year by a third-party individual.

Requirements enable less reprogramming of the machine and less generation of material. Projects with communication histories experience 15 percent less costs because of unplanned changes.

Risk related to the transfer of information is taken on by one partner. For example, design comments are directly fed back to production planning, while in multi-vendor systems, context is lost in between stages.

Author Bio

The author is a precision manufacturing specialist working with LS Manufacturing, which supports engineers and researchers in solving complex problems within the aerospace, medical, and automotive industries through advanced CNC solutions. Ensuring certified quality with AS9100D and IATF 16949, this team makes sure the results are top-notch through digital collaboration tools. Contact them for a free project review and DFM analysis to bring your concept to cost-effective reality.