Introduction

In industries where efficiency, reliability, and operational flexibility are critical, Self-Priming Pumps have become an indispensable choice. These pumps are designed to remove air from the suction line and begin pumping without manual priming, saving both time and labor. Across sectors such as mining, construction, wastewater management, and agriculture, the need for pumps that can handle demanding conditions without frequent intervention has driven the widespread adoption of this technology.

Understanding How Self-Priming Pumps Work

The primary advantage of Self-Priming Pumps lies in their ability to maintain prime even when the suction line is not filled with liquid. This is achieved through a specially designed pump casing that retains enough liquid to mix with incoming air, creating a vacuum to draw in more liquid from the source. Many modern designs incorporate centrifugal self-priming technology, which allows for rapid re-priming after the pump is stopped and restarted, ensuring minimal downtime in critical applications.

Unlike conventional pumps that require manual filling before operation, self-priming systems reduce start-up complexity, making them highly suited for environments where pump access is difficult or where operations run around the clock.

Applications Across Multiple Industries

The versatility of Self-Priming Pumps allows them to perform efficiently in various industrial settings. In construction, they are often used for dewatering excavations and removing excess water from foundations. In agriculture, they are employed for irrigation and livestock water supply. Municipalities rely on them for stormwater and sewage management, while mining operations depend on them for slurry and water transfer.

When paired with industrial water transfer pumps in larger systems, self-priming units can handle challenging fluid types, including those with suspended solids. Their ability to operate reliably in harsh conditions makes them valuable in remote sites where maintenance opportunities are limited.

Benefits That Boost Productivity

One of the standout benefits of Self-Priming Pumps is their operational efficiency. The integration of efficient fluid pumping solutions ensures that industries can move large volumes of water or other fluids without delays caused by re-priming or manual intervention. By reducing downtime and the labor associated with pump maintenance, companies can see a direct impact on productivity.

Another advantage is their adaptability. Self-priming models can be designed to handle everything from clean water to abrasive slurries. This adaptability means industries can standardize pump types across different applications, reducing training requirements for operators and simplifying spare parts management.

Design Features That Make a Difference

Modern self-priming systems incorporate robust materials and engineering to handle demanding environments. Centrifugal self-priming technology enhances pumping performance by providing high flow rates and reliable priming even after extended idle periods. This makes them ideal for applications like flood control or emergency pumping, where pumps may remain inactive for long durations but must start instantly when needed.

Some designs also integrate features like solids-handling capabilities, corrosion-resistant materials, and noise-reduction housings. These features extend pump life, reduce environmental impact, and improve workplace safety.

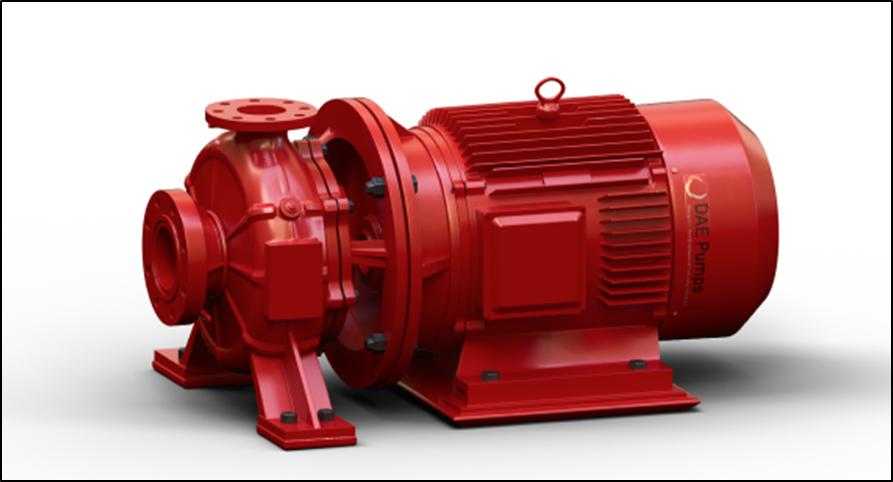

Why Many Industries Choose DAE Pumps

While the concept of Self-Priming Pumps is widely known, not all models perform equally in real-world conditions. DAE Pumps has earned recognition for delivering durable, high-performance solutions that stand up to the harshest industrial environments. Their engineering expertise ensures that each pump is optimized for longevity, energy efficiency, and ease of maintenance.

DAE Pumps offers models tailored for both light-duty and heavy-duty applications, ensuring customers can find the right match for their operational needs. Whether paired with industrial water transfer pumps for large-scale operations or used independently in localized settings, these pumps are built to maintain reliability over time.

Enhancing Operational Efficiency Through Technology

The integration of efficient fluid pumping solutions into self-priming systems has allowed industries to maximize output while minimizing costs. Features like quick re-priming, energy-efficient motors, and advanced seal designs contribute to lower operational expenses and extended pump life.

In sectors such as wastewater treatment, these pumps help ensure continuous flow in systems that must operate without interruption. In mining and dredging, they are often deployed to move water mixed with sediment, a task made easier by centrifugal self-priming technology that can handle fluid variations without losing efficiency.

Sustainability and Maintenance Advantages

Reducing environmental impact is increasingly important across industries. Self-priming models often require less fuel or electricity compared to older systems, lowering greenhouse gas emissions. Their ability to operate without frequent maintenance also means fewer replacement parts and less waste over time.

From a maintenance perspective, pumps that integrate industrial water transfer pumps into their design often require only routine inspections and simple servicing. This reduces the need for highly specialized technicians on-site and helps prevent costly downtime.

Looking Ahead: The Continued Role of Self-Priming Pumps

As industries evolve and face more complex operational demands, the role of Self-Priming Pumps will only grow. Their ability to deliver reliable, efficient performance in challenging conditions makes them a sound investment for long-term productivity. With ongoing innovations in materials, sealing systems, and centrifugal self-priming technology, these pumps are becoming even more capable of handling diverse fluid types and operating environments.

For companies seeking dependable performance, incorporating solutions from trusted providers like DAE Pumps ensures not just functionality but also lasting value. Whether deployed for routine water transfer, emergency response, or specialized industrial processes, these pumps continue to prove their worth in industries around the world.