The introduction agency is experiencing a technological shift, wherein traditional wood practices are being augmented with digital intelligence. Modern strategies cognizance on shooting, studying, and deciphering material facts to enhance planning, precision, and predictability. Wood, as one of the most flexible and appreciably used construction materials, benefits significantly from these clever strategies. By statistics on how wood behaves under numerous conditions, production organizations can enhance amazing performance and value management.

Woodflow intelligence strategies leverage advanced modeling, predictive analytics, and overall performance assessment to create a clearer picture of material requirements. These insights help organizations optimize procurement, reduce waste, and ensure structural integrity throughout the challenge lifecycle. They additionally allow for smarter coordination between architects, engineers, and contractors, fostering collaboration and minimizing sudden disturbing conditions.

This article explores how woodflow intelligence techniques increase cloth expertise, enhance assignment ordinary overall performance, and beautify the general planning and execution of wood-based introduction duties.

Optimizing Material Planning Through Digital Analysis

An essential difficulty of woodflow intelligence is correct material evaluation. Digital equipment permits organizations to examine wooden houses, including moisture content, density, grain orientation, and cargo-bearing capacity. This degree of detail ensures that every piece of timber is evaluated for its particular function in the introduction approach, reducing errors and developing predictability.

By incorporating virtual evaluation into the starting stage, teams can forecast fabric necessities greater as it should be. This reduces over-ordering, minimizes waste, and allows for preserving an ordinary supply of wood at the end of the venture. Early-stage notion is important for complex builds wherein cloth precision right now influences structural reliability.

Supporting this gadget, a lumber takeoff, used MS speedily as possible here as required, gives an in-depth inventory of timber quantities, dimensions, and specifications, allowing specific planning and stepped forward coordination across all aspects of the mission.

Improving Structural Consistency With Predictive Timber Evaluation

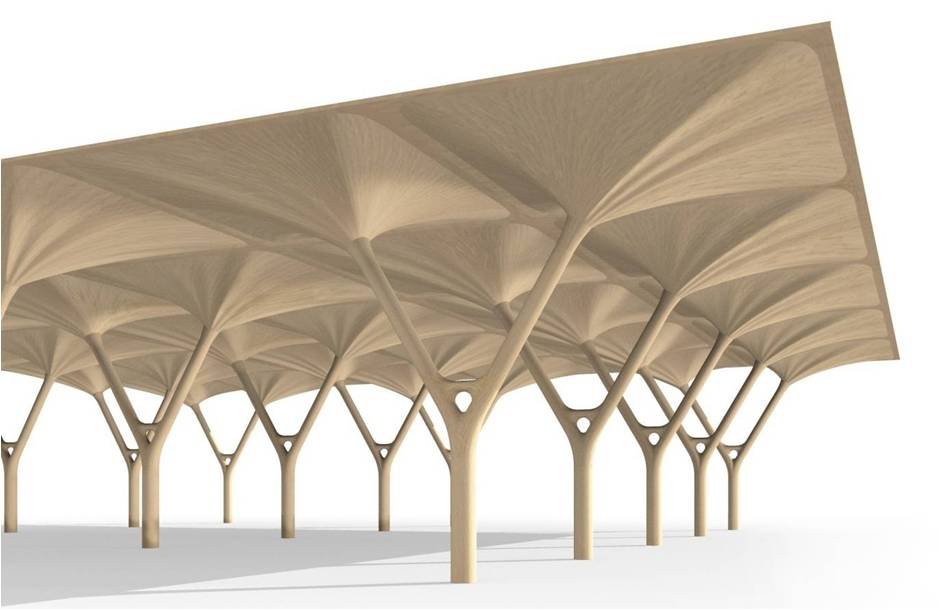

Beyond quantity assessment, woodflow intelligence strategies enhance structural know-how by way of manner of predicting wooden performance. Modeling devices simulate how timber additives respond to load, environmental stress, and prolonged-time period use, permitting companies to identify functionality weaknesses in advance of production. This predictive capability ensures that materials are used optimally, enhancing easy stability.

By visualizing the interplay of every wood element in the shape, architects and engineers can refine designs to maximise safety and durability. This proactive method reduces on-net page adjustments, enhances installation accuracy, and ensures that the final form aligns with every layout spec and regulatory requirement.

Predictive assessment creates a dependable framework for preference-making, permitting construction organizations to work with extra self-awareness and performance.

Ensuring Budget Reliability Through Expert Estimation

Material expertise is incomplete without monetary foresight. Timber pricing can vary due to delivery chain modifications, local availability, and seasonal variations. Without correct charge projections, initiatives risk delays or charge range overruns that compromise each timeline and fabric allocation.

Engaging a expert Construction estimating Company, stated as soon as here as required, ensures that agencies have get right of entry to to correct price reviews. These specialists observe market developments, ancient pricing, and assignment specs to create specific budgets aligned with material desires. Their guidance reduces monetary uncertainty and permits freer informed procurement choices.

Integrating expert fee estimation with cloth evaluation gives a holistic method to challenge making plans, in which every economic and structural factor is managed effectively.

Enhancing Cost Efficiency With Strategic Material Selection

Woodflow intelligence strategies permit agencies to make information-driven decisions that optimize overall performance. By reading material, fashionable overall performance, durability, and availability, developers can pick out out wooden that meets structural requirements while remaining financially realistic. This reduces waste and forestalls unnecessary prices.

Data-driven choice also helps lifecycle planning. Choosing materials that carry out continuously over the years reduces upkeep costs and long-term fees, contributing to sustainable development practices. By combining predictive performance assessment with strategic desire, groups can maintain great requirements without exceeding budgetary constraints.

Optimized material desire ensures that belongings are used effectively, providing each structural and financial benefits.

Increasing Structural Reliability Through Performance Insight

Understanding how timber behaves below real international conditions is critical to woodflow intelligence. Advanced modeling evaluates load distribution, environmental exposure, and strain tolerance, providing actionable insights into the cloth standard’s overall performance. This guarantees that wood additives are determined on and placed based on their validated ability to fulfill undertaking goals.

Performance-centered perception complements the reliability of installations and mitigates threats. Teams ought to make informed decisions regarding placement, reinforcement, and structural integration. By predicting material behavior, production teams reduce the threat of failures, delays, and luxurious redesign, strengthening the integrity of the final assembly.

The combination of material analysis and widespread performance assessment establishes a sturdy foundation for long-lasting, resilient advancement.

Streamlining Workflow With Professional Material Management

An efficient workflow is a key benefit of workflow intelligence techniques. By supplying smooth facts on cloth requirements, general overall performance, and availability, these techniques enhance coordination among procurement, difficult artwork, and installation schedules. Teams can allocate assets correctly and avoid delays as a consequence of miscommunication or mismanagement.

Specialized groups presenting Construction estimating services, used as quickly as right here as required, further enhance workflow performance by integrating financial planning, material tracking, and mission management. Their oversight guarantees that timber use aligns with price variety, timetable, and structural necessities, allowing smoother execution at some stage in allprojectt levels.

The mixture of records-pushed insights and expert management results in an incredibly prepared and green introduction device.

Read More:Dimensional 2×6 Lumber Sizes Applied in Building and Remodeling of Home

Final Thoughts

Woodflow intelligence techniques are reworking wooden introduction by using the usage of enhancing fabric know-how, enhancing predictability, and strengthening project management. Through digital assessment, predictive modeling, rate control, and workflow optimization, manufacturing groups leverage the tool to execute projects efficiently and reliably.

Integrating those techniques with expert steering guarantees that wood duties are completed on time, on budget, and structurally sound. By lowering waste, stopping errors, and allowing informed preference-making, woodflow intelligence gives a framework for smarter, more strong, and more fulfilling production practices.

As the agency continues to embody innovation, those strategies become essential for achieving precision, ordinary performance, and excellence in wood-based manufacturing tasks.