Every era of design has its defining moment, the point when imagination stops being limited by the tools that bring it to life. For today’s creators, that moment is now. For decades, manufacturing dictated what could and couldn’t be built, forcing designers to compromise bold ideas in favor of what was merely possible.

But with multi jet fusion, those constraints are falling away. This isn’t just another 3D printing upgrade, it’s a creative revolution. By merging speed, precision, and design flexibility, MJF empowers engineers, artists, and innovators to move beyond the boundaries of traditional manufacturing. From concept to production, it transforms creative potential into tangible results, faster, smarter, and without compromise.

What Makes Multi Jet Fusion Technology Such a Game-Changer

Every creative breakthrough starts with grasping why it works differently. This 3d printing technology represents more than a modest upgrade, it’s a total reimagining of how we build things.

Core Strengths That Remove Design Limitations

What’s the real breakthrough behind this new wave of design freedom? It lies in how multi jet fusion eliminates the physical and financial barriers that used to hold creativity hostage. Instead of forcing designers to simplify their concepts for manufacturability, this advanced 3D printing process adapts to the design itself.

Every microscopic detail, from wall thickness to texture, is customizable, empowering designers to bring their most ambitious ideas to life without compromise. This level of freedom reshapes the entire creative process. You no longer have to choose between aesthetics and practicality or scale back a concept because of tooling costs.

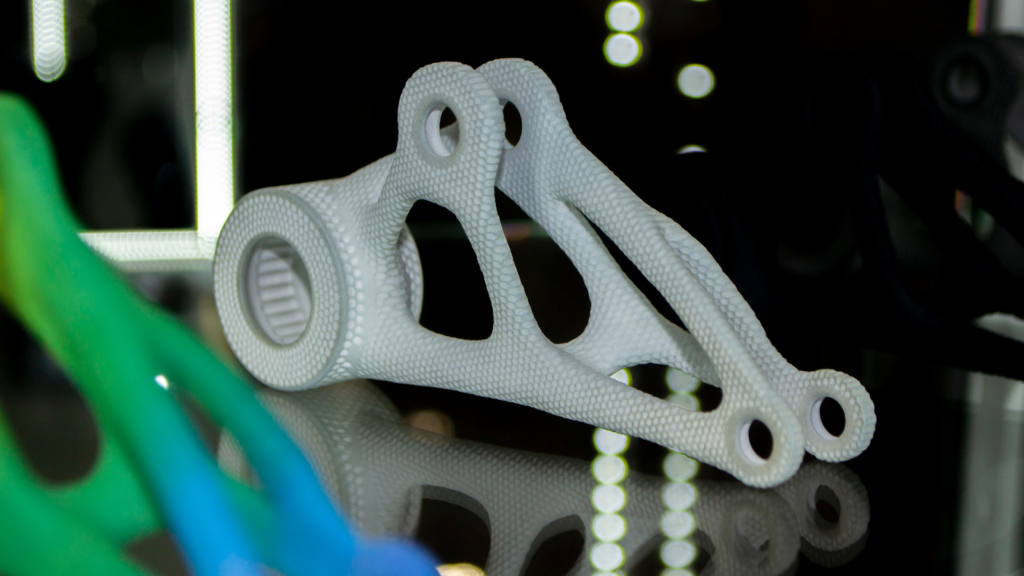

By removing traditional constraints, multi-jet fusion allows parts to be both structurally optimized and visually refined. Whether it’s lightweight aerospace components, ergonomic medical devices, or intricate consumer products, this technology ensures that creativity is never limited by manufacturing.

With multi-jet fusion, tooling investments vanish from your upfront costs. Intricate parts cost basically the same as simple ones. You can consolidate assemblies, reduce component counts, and experiment with unconventional concepts without the financial penalties that normally strangle innovation before it breathes.

Real-World Creative Applications Reshaping Multiple Sectors

Technical capabilities matter, sure, but what are people actually building with this newfound freedom? The applications emerging across different industries reveal enormous creative potential that was just waiting for the right tools.

Product Design Gets a Complete Makeover

Product designers are now playing with parametric designs that respond to actual user data. Mass customization has moved beyond marketing hype into genuine scaled production. Living hinges print as unified pieces. Biomimicry-inspired structures that once required months for prototyping now materialize in days. Want texture variations for specific tactile experiences? Handle it in one print session.

Transforming Fashion and Medical Fields

Fashion designers craft custom-fitted accessories and footwear featuring personalized comfort zones. Healthcare providers produce patient-specific prosthetic devices that merge functionality with individual aesthetic preferences, addressing both practical requirements and emotional needs.

These creative 3d printing applications aren’t gimmicks. They’re solving genuine challenges for actual people who need tailored solutions instead of mass-market products designed around mythical average measurements.

The Practical Benefits Driving Creative Freedom

Beyond the impressive factor lies something more substantial. The tangible advantages create conditions where experimentation becomes financially reasonable.

Design Freedom That Traditional Methods Can’t Touch

Draft angles? Irrelevant now. Worried about undercuts? Don’t be. Variable wall thickness within single components is routine. Organic shapes transfer smoothly from design software to tangible objects without the compromises that traditionally murdered creative concepts.

Making Experimentation Economically Sensible

Let’s discuss the financial reality. Complex geometries don’t inflate per-unit costs like they do with machining or molding. No tooling investment haunts your balance sheet. Small production quantities make economic sense.

Material waste decreases substantially compared to subtractive manufacturing methods. This economic transformation means you can test five design variations instead of settling for one. You can pivot based on customer feedback without destroying your budget.

Compressed Development Timelines

Same-day prototypes have become routine. Design validation happens almost instantly. Testing multiple versions simultaneously becomes standard operating procedure rather than expensive luxury. Product development cycles shrink dramatically, letting smaller operations respond to market shifts as quickly as established corporations.

Where Creative Multi Jet Fusion Applications Are Heading

Looking ahead, emerging patterns around this technology suggest we’re barely scratching the surface. When different technologies converge, possibilities appear that nobody anticipated even recently.

Sustainability Meets Creativity

Here’s something worth noting: 38% of manufacturers are actively pursuing increased sustainability in their operations. Additive manufacturing aligns perfectly with this objective through recycled powder programs and on-demand production that eliminates overproduction waste.

Local manufacturing cuts shipping-related carbon emissions. Circular economy models become feasible. Development of biodegradable materials is gaining momentum as demand increases.

Blending Digital Workflows with Physical Products

The merger of physical and digital creation is accelerating rapidly. Virtual reality design validation occurs before anything gets manufactured. Digital prototyping workflows connect designers on different continents seamlessly. Metaverse-to-physical production pipelines might sound futuristic, but they’re already in testing phases.

Embedded sensors within printed components, integrated antenna structures, and conductive pathways are creating entirely new product categories that unite physical and digital capabilities.

Taking Your First Steps with Multi Jet Fusion

So this sounds appealing, what comes next? Implementation doesn’t need to feel overwhelming when you tackle it strategically.

Assessing Your Design Compatibility

Begin by examining your current designs through the MJF perspective. Which limitations have you been accepting unnecessarily? Verify minimum wall thickness specifications (they’re thinner than you’d expect). Explore internal structures that weren’t previously viable. Identify assembly consolidation opportunities.

Selecting Service Partners or In-House Equipment

Organizations provide bureau services that allow technology testing without capital expenditure. Their instant quote systems deliver immediate cost feedback. For higher production volumes, in-house equipment investment starts making financial sense, though break-even calculations vary significantly based on your specific applications and volume requirements.

The advantages of multi jets become most apparent when you match the technology to suitable applications instead of applying it universally.

Questions People Ask About Multi Jet Fusion

Voxel-level control offers detailed management that surpasses most alternatives. Build speeds dramatically exceed many competing systems. Material properties deliver genuine functional strength appropriate for end-use applications, not merely visual mockups.

Turnaround timing depends on component complexity and your service provider, though same-day prototypes are standard for straightforward geometries. Production batches typically finish within days instead of the weeks conventional manufacturing demands.

Definitely. The elimination of tooling costs means economic viability begins at single units. Break-even analyses comparing MJF with injection molding typically favor MJF up to several thousand units, depending on component complexity.