Introduction

In the medical device manufacturing business, communication-related errors often cause prototype development, cost, and quality glitches, ultimately affecting patients. The underlying issue often times is related to the traditional method of manufacturing, which fails to employ data transfer and control, causing a misalignment between creation and design.

This current topic will discuss how the integration of precision CNC machining technology can maximize communication, translating a design flawlessly into a quality medical device. The ensuing sections will delve into a thorough examination of how CNC machining solves these crucial issues.

Why Medical Device Manufacturing Needs High-Precision CNC Machining?

The manufacturing of medical devices demands exceptionally high standards of precision and reliability, as dictated by international quality standards like ISO 13485. Any deviation can compromise device function and patient safety.

The Limitations of Traditional Manufacturing

Conventional machining systems involve manual interpretation of 2D drawings and descriptions, which introduce many opportunities for misunderstandings between design and engineering and machine shop staff. Every change in design involves a complex loop of re-communication, re-tooling, and re-validation, making it rather time-consuming to have design and iteration in an optimized manner. This kind of communication loop is basically one of the main reasons that introduce errors in components, which are produced inappropriately and hence result in rework.

How CNC Machining Ensures Automated Consistency

- Digital Thread Integration

Precision CNC machining replaces error-prone manual communication with a seamless digital thread. The process begins with a 3D CAD model, which is directly translated into machining instructions (G-code) via CAM software. This digital continuum ensures that the design intent is perfectly encoded and executed by the machine, eliminating subjective interpretation errors.

- Unmatched Precision and Repeatability

CNC machines operate with micron-level repeatability, ensuring that every CNC machining parts produced is identical. This automation not only guarantees the high precision of a single component but also provides unparalleled consistency across production batches, shifting quality control from post-production inspection to in-process assurance. For critical features like countersink and counterbore holes, which are vital for assembly reliability, this precision is paramount.

CNC Machining How to Improve Customer Communication in Medical Prototype Development?

In this highly dynamic prototype development phase of medical devices, design changes come about often due to continuous clients’ feedback and tests. The cornerstone of success, however, lies in effective communication.

Often, clients-which may include medical companies or surgeons-require iterative adjustments. In traditional settings, each modification initiates a slow process involving re-design, re-quoting, and re-scheduling, leading to significant delays and misunderstandings that result in prototypes failing to accurately reflect the design vision.

The inherent digitalization of CNC machining can fundamentally enhance customer service in manufacturing. Working from a common 3D CAD model, clients and manufacturers can collaborate on one single digital twin. Design updates are immediately reflected in the machining program, and manufacturers can provide real-time DFM feedback. This transparent and efficient interaction model significantly reduces feedback loops. Therefore, faster and more accurate prototype iterations are possible, as also encouraged by governing bodies for early risk reduction. This minimizes misunderstandings and accelerates the path to market in health device prototyping.

What are the Key Advantages of Precision CNC Machining in the Medical Field?

The benefits of precision machining for the medical sector extend beyond basic accuracy, offering comprehensive precision communication solutions.Exceptional Accuracy and Tolerance Accuracy capable of maintaining a tolerance of +/– 0.005mm, necessary in high-end CNC machining products such as implants and surgery instruments.

- Comprehensive Material Compatibility:

Machines biocompatible materials such as medical stainless steel, titanium, and PEEK very effectively, making it the best option depending on the desired application. - Complete Traceability:

The electronic traceability process ensures all data necessary for traceability as per FDA and ISO guidelines can be logged.

These advantages collectively prevent the communication losses and errors that lead to rework and waste. Using CNC machined prototypes for validation before mass production significantly de-risks the later stages of product development.

How to Achieve Large-Scale Medical Device Production through CNC Machining?

Scaling-up from a company to mass production brings new issues regarding cost, efficient operations, and supply chain synchronization. High volume CNC machining works well in solving such issues.

High volume CNC machining relies on automation for material efficiency and economy of scale. For CNC machining metal parts, multi-axis machine centers can achieve all the processing steps for complex parts within one machine change, assuring accuracy and efficiency.

The integrity of the supply chain can be further enhanced by forging ties with suppliers who are ISO 9001 and AS9100D certified, as it ensures consistency and standardization in communication and processing. For instance,a company utilizes such certifications to ensure compliant and predictable workflows from order receipt to product delivery. Engaging professional CNC machining services is a critical step for achieving efficient and economical large-scale production of medical devices.

Case Study: How CNC Machining Solves Communication Challenges in Medical Manufacturing?

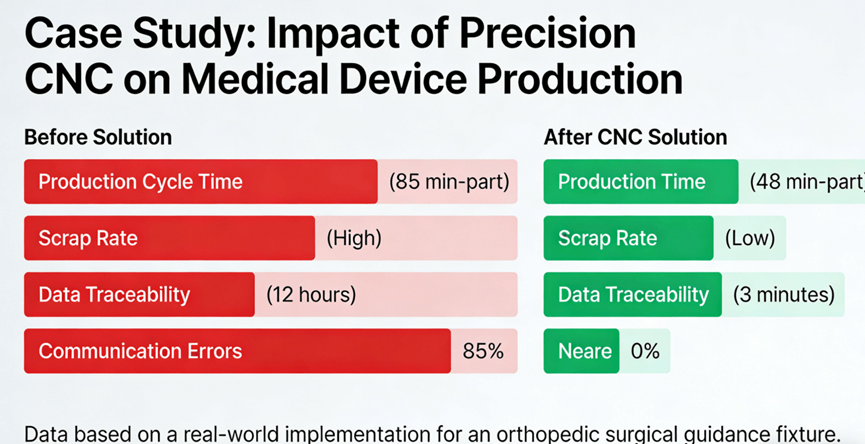

A real-world scenario illustrates the transformative impact of CNC machining.

Project Background and Communication Bottlenecks

A startup developing a new orthopedic surgical guidance fixture, characterized by a complex geometry and high requirements for lightweight and rigidity, faced significant delays using traditional outsourcing. Miscommunication regarding complex 3D surfaces via 2D drawings led to multiple errors and months of delays.

Implementing a Precision CNC Machining Solution

The company switched to a supplier offering integrated precision CNC machining services.

- Digital Collaboration

DFM analysis was conducted on shared 3D models, allowing real-time feedback.

- Rapid Iteration

CNC programming and machining quickly responded to changes, reducing iteration time from 3 weeks to 5 business days.

Quantifiable Results and Lessons Learned

By adopting a digital manufacturing process centered on how CNC machining improves communication, the startup reduced total development time by 20% and slashed prototype-stage communication errors by 85%. The key lesson is that integrating manufacturing expertise into the design phase via digital tools establishes a single source of truth, effectively breaking down communication barriers.

Conclusion

In conclusion, precision CNC machining technology is a revolutionary communication tool used in the manufacturing of medical devices. This technology entails a complete digital process, which ensures the lossless transmission and execution of information from the conceptual stage to mass production. This, in turn, addresses various disconnects presented in the conventional process, which yields increased efficiency, cost-effectiveness, and a sound basis to meet the various stringent regulations.

One should immediately approach a professional CNC machining service provider to have their specific requirement met and assessed by experts.

Author Biography

This article is based on the knowledge of the precision manufacturing specialist who has over 10 years of experience in the medical devices industry. He is specialized in CNC machining technology application and medical quality management systems (such as ISO 13485) .

FAQs

Precision parts like surgical instruments and implants are produced using CNC machining. Digital design eliminates errors that occur during human communication.

Biocompatibility materials, for example, medical-grade stainless steel and/or PEEK, and inspection procedures in relation to ISO standards, could be considered for selection.

Yes, by automation, the optimization of material usage and minimizing reworks, the overall cost can be reduced up to 30%, which will be mostly applicable for mass production.

This is made possible by the ability of integrated CAD/CAM systems to facilitate real-time sharing and feedback on designs.

ISO13485 and the FDA regulation are the most important certifications that provide a stable quality management system to meet the international market.